Complete packaging and palletizing solutions

VPEKS Automation excels in designing full palletizing lines for various items and delivering automated packing solutions for powders, liquids, and granules. Our global presence allows us to meet clients’diverse palletizing and packaging needs with reliable and innovative solutions.

About VPEKS

VPEKS Automation Co.,Ltd is a leading manufacturer of packing and palletizing machinery, offering integrated solutions for various industries for more than 15 years. We specialize in designing and supplying high-quality, efficient, and reliable machinery, as well as comprehensive after-sales services to ensure customer satisfaction.

Founded in 2007, VPEKS Automation specializes in the planning, research and development, and manufacturing of automatic packaging and palletizing equipment. With over 80 different types of packing and palletizing machines, including automatic palletizers, bag feeding automatic packing lines, ton bag filling machines, VFFS packing machines for powder, granules, and liquids, bottle filling production lines, wrapping machines, and conveying systems, we offer intelligent, flexible, and information-driven one-stop automatic packaging solutions. Leveraging the advantages of the automation industry chain, we integrate technology research and development, scheme design, product production, and customer field applications to meet our clients’ needs.

Fully automatic bag packaging and palletizing production line

A complete fully automatic packing line consists of an automatic bag feeder, automatic weighing machine, filled bag transfer conveyor, and automatic sewing machine. A complete fully automatic palletizing line includes an inclined conveyor, bag shaping conveyor, bag weight detection system, bag grabbing conveyor, automatic palletizing machine, pallet magazine, roller conveyor for pallets, etc.

High level palletizer

High-level palletizers provide efficient and space-optimized palletizing solutions with flexible pallet patterns, reduced labor costs, consistent quality, and integration capabilities. These automated palletizing systems enhance safety, increase throughput, and offer real-time monitoring, contributing to streamlined industrial processes. Explore the benefits of advanced palletizers for improved production efficiency, precision, and overall workflow optimization.

Automatic filling and capping line

Our automated filling lines handle liquids or dense products like creams, sauces, and jams, as well as powders and small particles such as milk powder, salt, and sugar.

The fully automatic bottle filling line can be customized to meet the specific needs of the client. It includes a bottle cleaning system, automatic bottle dispenser, multi-head automatic filler, automatic capping machine, and automatic labeling machine.

Single column palletizer

The Single column palletizer by VPEKS Automation offers the advantage of handling a maximum load capacity of 100kg for various types of products such as bags, cases, and barrels. Additionally, it provides a high palletizing speed of 400 to 600 cycles per hour, making it efficient for rapid palletizing operations. It also has features of small footprint, high cost-effectiveness, and is sturdy and durable.

Robotic palletizer

Robot palletizers offer numerous advantages, including high speed, flexibility for various working conditions, and the ability to handle high loads. As a provider of robotic palletizers, VPKES offers a range of trusted brands such as ABB, KUKA, Fanuc, Kawasaki, Yaskawa, ESTUN, and more. This variety of options allows customers to choose the best solution for their specific needs. We will program the robotic arm to meet different palletizing requirements.

High speed is an important advantage of robotic palletizers, as it can help increase productivity and reduce labor costs. Additionally, the flexibility of these machines allows them to adapt to different working conditions, making them a versatile solution for various industries. The ability to handle high loads is also crucial, as it ensures that the palletizer can handle a wide range of products and materials.

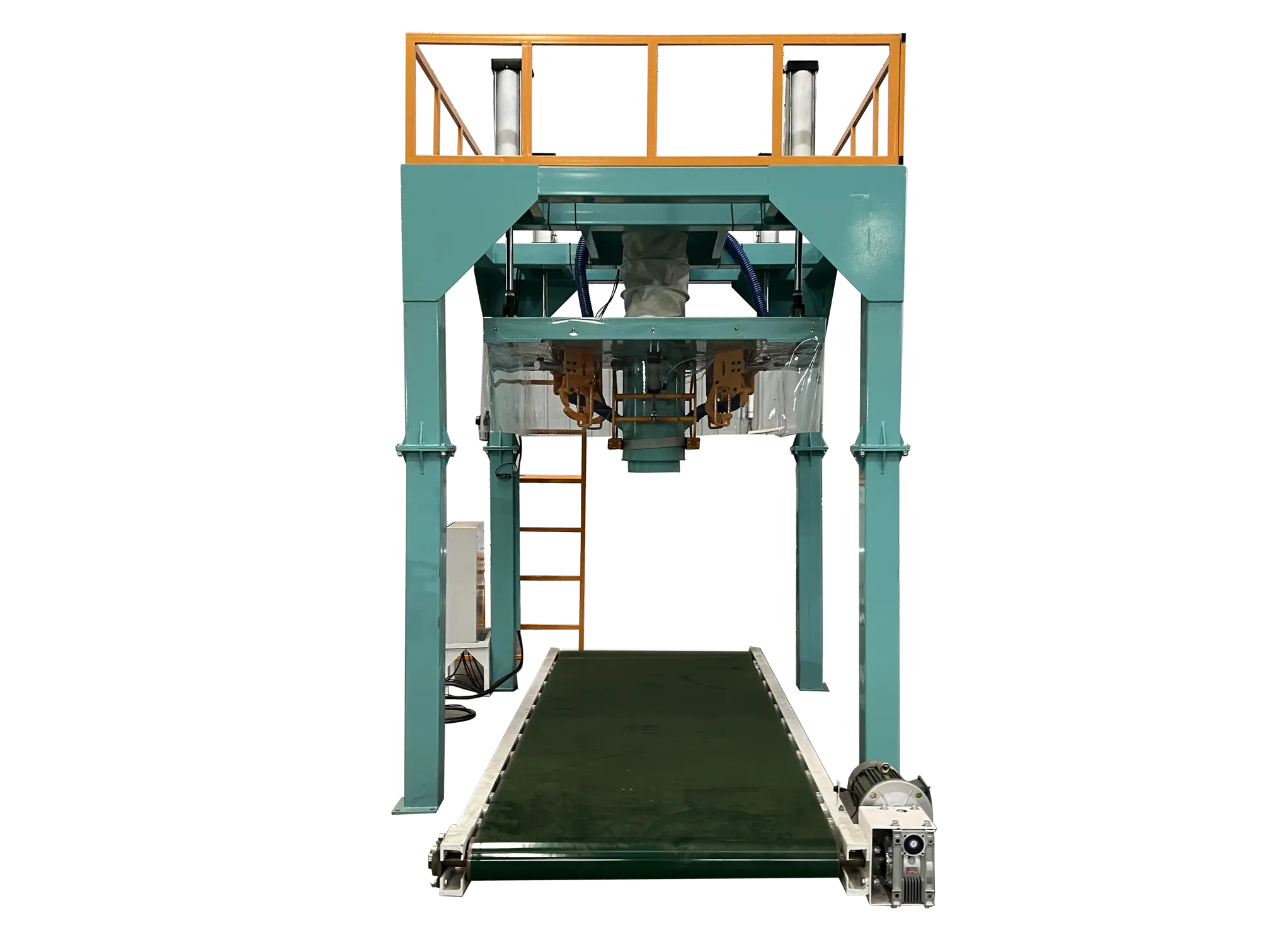

FIBC Ton Bag Packing Machine

The ton bag filling machine, also known as a jumbo bag packing machine or bulk bag filling machine, is designed for automated weighing and filling of bags ranging from 200kg to 1000kg. It offers high accuracy and speed in the filling process.

Sachet Bag VFFS Packing machine

The VFFS packing machine, also known as the vertical form filling sealing machine, transforms plastic films into bags and fills raw materials into these small bags. It can also be referred to as a sachet filling machine or stick bag packing machine. With the ability to change the top filling system, the VFFS packing machine, manufactured by VPEKS Automation, can accommodate various substances such as powder, granules, liquids, or pastes. It operates at high speed and ensures effective sealing, offering options for 3-side seal, pillow seal, or 4-side seal. Additionally, if there is a need to pack different sizes of stick bags, purchasing an additional bag former for the machine is advisable.

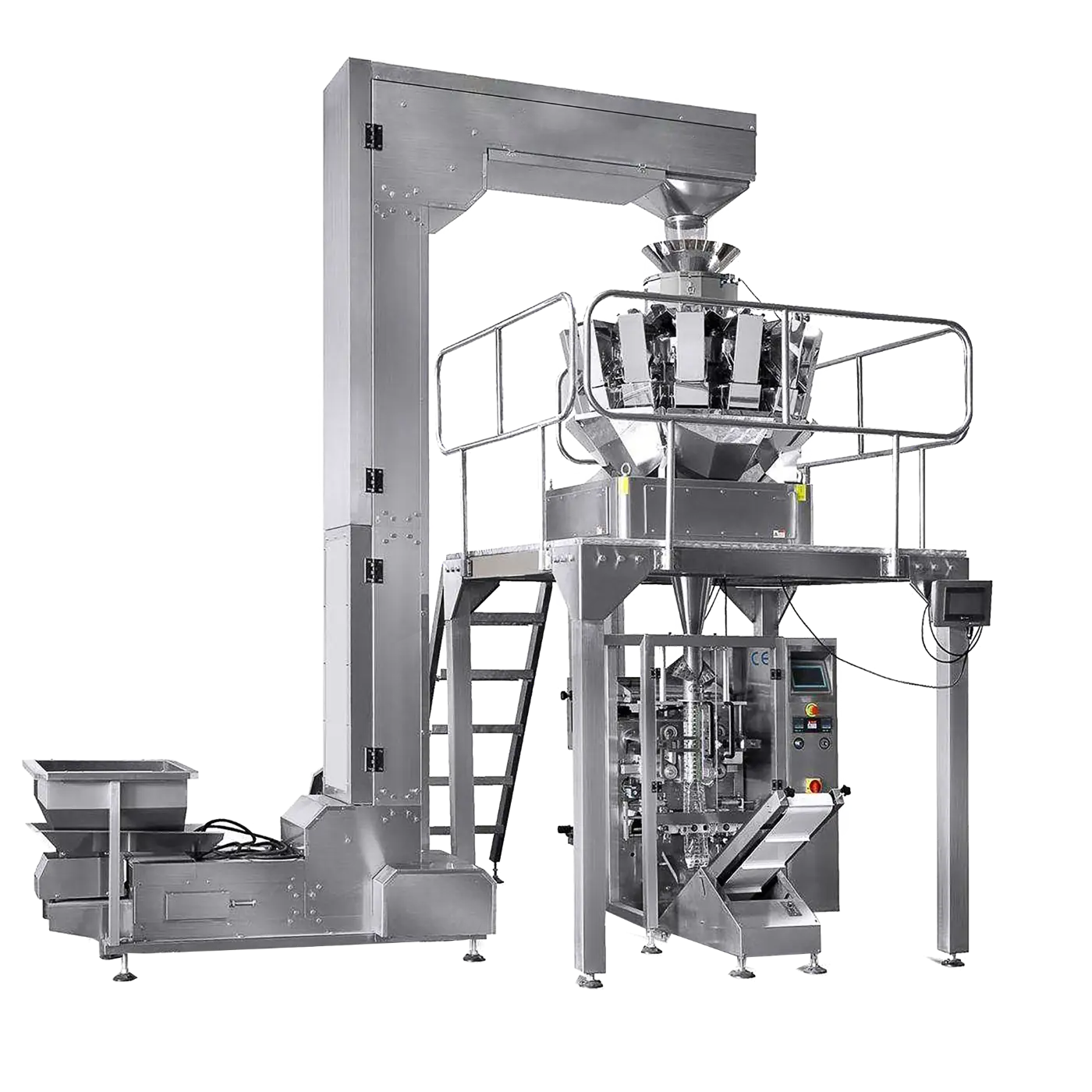

Multi-head weighing and filling machine

The multi-head packing machine consists of a feeding conveyor (or bucket elevator), multi-head weigher, and bag forming filling machine. It boasts high accuracy and adjustable packing speed, making it ideal for packing various raw materials such as grains, coffee beans, sugar, salt, and more. Additionally, it can efficiently pack uneven and irregular materials like charcoal lumps, coal lumps, and pet feed. VEPKS offers the most suitable models based on the characteristics of the raw materials, target output, and bag size. The maximum width of the bags can be 550mm.

Automatic Pouch(Doybag) feeding packing machine

For premade pouches, we offer simplex, duplex, and quadruplex FFS pouch filling machines under our brand VPEKS. These machines can also be used for zipper doypacks or other types of stand-up bags. Our VPEKS doypack packing machines, certified by CE and FDA, offer high speeds and dosing precision, saving labor costs for our clients.